Introduction

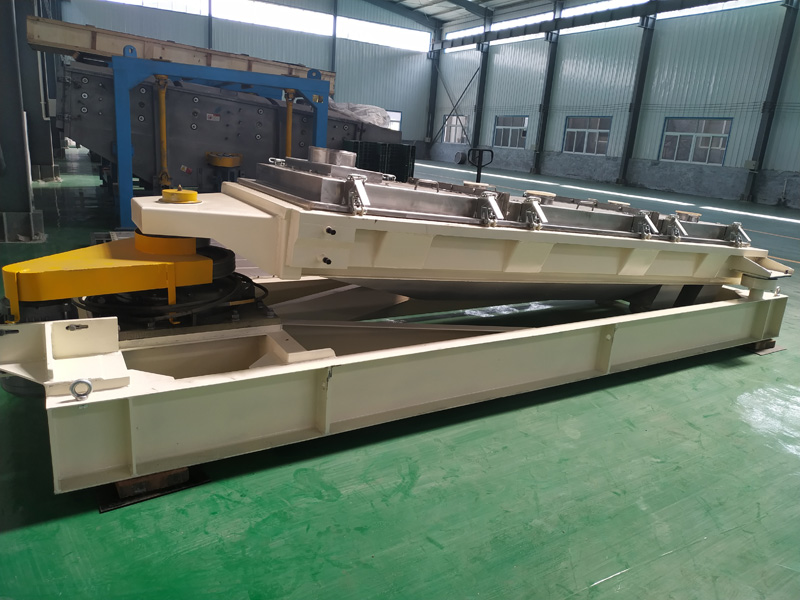

Gyratory screen is also called gyratory screener, gyratory sifter, gyratory separator, gyratory screening machine, rectangular gyratory sifter, reciprocating screen etc. It is used for high precision and large capacity screening for 40 μm~10mm granules.

1. Balanced operation, strong structure, durable and continuous operation and low failure rate.

2. Super large capacity (2~150 t/h). And the screening accuracy is as high as 90-99%.

3. Use the bouncing balls to clear the screen and prevent the mesh from blocking effectively.

4. The screen is only loaded in the vertical direction and does not vibrate. The service life of screen is 5-100 times that of ordinary vibrating screen.

5. The three kinds of clips for tensioning screen are easy to disassemble and the replacement of the screen is convenient. The screen mesh is tightened automatically. The top cover is installed with self-adjusting clamps to realize quick disassembly and assembly.

6. Applied to 10mm to 40μm particle grading, up to 4 layers of screens. Can also use a mesh for duplex screening.

7. The whole machine runs smoothly. It can be mounted by seat or suspended.

8. Fully enclosed structure, no dust, noise below 80 decibels.

what makes us different

Benefits of Side Access

Door Gyratory Screen

1. The side access door type gyratory screen realizes the screen replacement from one side or both sides of the screen box.

2. Each deck of the side access door type gyratory screen is composed of multiple independent small screen frames, which are light in weight.

3. The side access door type can directly replace any layer of the screen without moving the upper screen frames or cover, saving unnecessary work.

4. For the side access door type gyratory screen, people only need to replace the small piece of damaged screen, and no need to replace the whole layer of screen, which saves much cost.

5. The side access door type makes the screen replacement easy, only one or two people can complete the work, which saves much time.

6. The screen replacement operation is safe. Since each layer of the screen is divided into 2~8 separate small screen frames, each screen frame is light, which is safe for the operator.

7. Since the weight and area of the small screen frame are 1/2 to 1/8 of the whole layer, there is no need to use any auxiliary equipment such as hoist, crane etc. when replacing the screen, and the screen replacement is faster.

8. Since the use of small screen frames, there is no more space required when replacing the screen, which saves much installation and maintenance space.

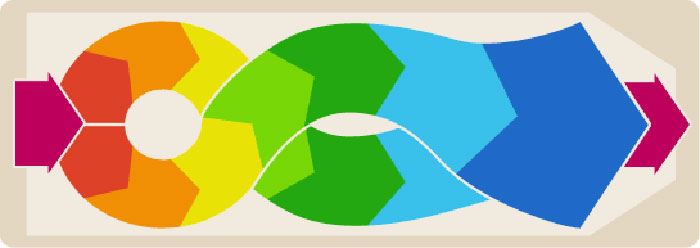

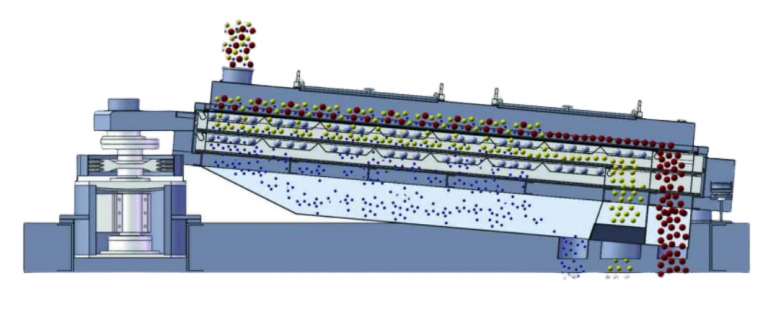

Working Principle

The gyratory reciprocating motion of gyratory screen begins with a circular motion at the feed end, gradually diminishing along the length of the machine to elliptical movement in the middle, and finally to an almost straight-line motion at the discharge end.

Technical Parameters

General Purpose Type

| Model | Screen Area (m²) | Layers of Screen | Power (KW) | Ref. Dimensions (mm) |

| AD-515 | 0.75 | 1~2 | 1.5 | 3050*766*1500 |

| AD-1021 | 2.1 | 1~2 | 3 | 3900*1310*1800 |

| AD-1030 | 3 | 1~4 | 4 | 4900*1310*1800 |

| AD-1036 | 3.6 | 1~4 | 4 | 5500*1310*1800 |

| AD-1530 | 4.5 | 1~4 | 5.5 | 4900*1958*2100 |

| AD-1536 | 5.4 | 1~4 | 5.5 | 5500*1958*2100 |

| AD-1836 | 6.48 | 1~4 | 7.5 | 5500*2238*2100 |

| AD-1840 | 7.2 | 1~4 | 7.5 | 5900*2238*2100 |

| AD-2050 | 10 | 1~4 | 11 | 6800*2500*2100 |

| Model | Screen Area (m²) | Layers of Screen | Power (KW) | Ref. Dimensions (mm) |

| ADC-515 | 0.75 | 1~2 | 1.5 | 3300*810*1800 |

| ADC-1021 | 2.1 | 1~2 | 3 | 3900*1310*1800 |

| ADC-1030 | 3 | 1~3 | 4 | 5400*2120*2100 |

| ADC-1036 | 3.6 | 1~3 | 4 | 6000*2120*2100 |

| ADC-1530 | 4.5 | 1~3 | 5.5 | 5400*2620*2590 |

| ADC-1536 | 5.4 | 1~3 | 5.5 | 6000*2620*2590 |

| ADC-1836 | 6.48 | 1~3 | 7.5 | 6000*2920*2590 |

| ADC-1550 | 7.5 | 1~3 | 7.5 | 7250*2620*2590 |

Side Access Door Type

Installation

1.Seat Installation

As the driving system of this machine has a balance function, outward transmitting force is smaller, it can be installed directly on the ground, or steel structure frame or platform that allow vibration.

Direct Discharge Type

Forward Type

2.Cable Suspension Installation

The sieving machine can be hoisted by cables from the four corners of the machine to insulate the balance force of the sieving machine from the surrounding structure.

Direct Discharge Type

Forward Type

Details of Our General Purpose Gyratory Screen: Click to enter

Details of Our Side Access Door Gyratory Screen: Click to enter

Application

The gyratory screen can be widely used for screening sugar, salt, soybeans, milk powder, starch, silica sand, frac sand, calcium carbonate, limestone, silicon metal powder, petroleum coke, activated carbon, graphite, fertilizer, urea, soda ash, detergent, plastics, crumb rubber, battery material, wood chips, wood powder etc.