Gyratory Sifter

Introduction:

Simple pursuit of sieving accuracy will be at the expense of yield, while the pursuit of large yield will decrease the accuracy.

The gyratory sifter is a kind of high precision and large yield efficient screening equipment which is specially designed for the above problem. With the characteristics of low failure rate, low downtime rate, low cost, and high output, high precision, high highly efficiency, it is the classic model of our company.

This machine has the screen sides tensioning device and the ball cleaning system, which provide the maximum horizontal amplitude, making the qualified product screening rate reach the highest. In addition, it has a huge screening capacity.

This gyratory screener can be equipped with one to five layers of screen, which can complete the sieving from 12 mesh to 325 mesh. It can be designed as duplex screening to make it more productive. The design is compact and energy efficient.

Features

- The unique reciprocating motion makes the whole screen surface have the equivalent screening efficiency, which can realize the large yield and high precision screening.

- Quick-open type hinged door and rapid screen mesh tension system ensure quick replacement and inspection of screen mesh.

- The unique suspension system makes the whole machine run smoothly. The sieving machine itself is less destructive. The basic dynamic load is low and the equipment does not need to be fixed.

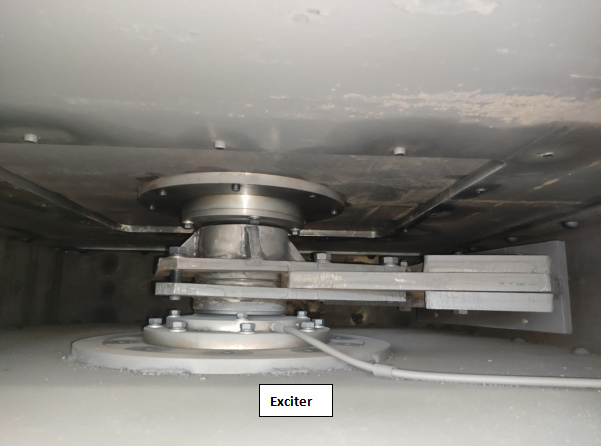

- Vibration exciter is maintenance-free within 2 years. Adopt high quality lubricating grease, high quality sealing ring and high quality sealing bearing.

- The dynamic balance drive increases the exciter’s rotation speed from 150~180 RPM to 300 RPM.

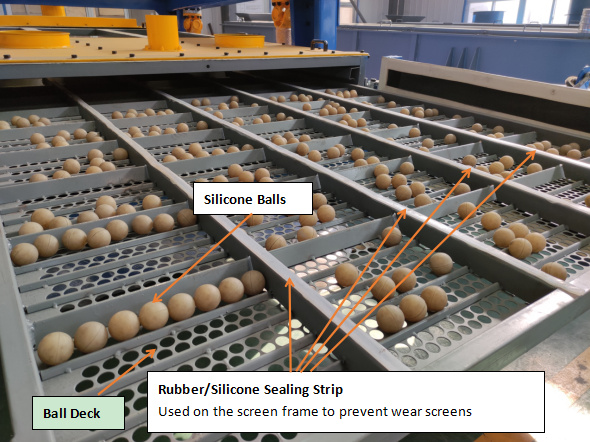

- The high speed rotation of the exciter improves the acceleration value of the elastic ball, so that the elastic ball impacts screen surface more powerfully. The screen mesh is not easy to plug, prolonging the service life of the screen, reducing the downtime, and ensuring the continuity of screening.

- Fully enclosed structure and dust-free.

- The movement of the screen machine, the screen mesh protection support design, and the effective cleaning of the elastic ball make the screen service life long.

- Soft running and low noise.

- Larger capacity. Duplex screening is available.

- Forward stretch material discharging, easy to collect.

How to replace the screen?

Working Principle

The full gyratory movement quickly spreads, stratifies and separates the materials, and the horizontal and uniform rotation makes each area of the screen have the consistent screening action and efficiency, which improves the processing capacity of the machine and realizes large capacity and high efficiency screening.

The stroke, rotation speed and screen slope angle can be customized, and the stroke and rotation speed can be optimized on site to improve the screening performance for different products.

The rotating motion pushes the bouncing balls under the screen to continuously hit the screen, so that the wedged particles and near-size particles are ejected, keeping the screen clean. The large horizontal amplitude also effectively improves the screening effect of near-size particles. According to different applications, people can choose 50mm, 40mm or 30mm bouncing balls.

3 greatest strengths of our Gyratory Sifter compared to products produced by other Chinese suppliers in the market:

- The exciter can be disassembled and assembled as a whole, which is very convenient for repair and maintenance;

- The vibration exciter adopts high-quality bearings and running parts, and has a long service life;

- The material can be full of the whole screen surface, effectively using the screen area.

Technical Parameters

- Rotation speed: 180~330 rpm, and can be fine-tuned

- Range of Screen Slope: 3°~7°

- Products: up to 12 layers of screen, screening area: 3~73.5 square meters, can produce up to seven products

- Adjustable stroke: 15~50mm

- More designs:

Countercurrent screen: The discharge port is directly below the feed port, which is convenient for the connection of the system.

Compound screen: Multiple screens with the same mesh size can be combined on a sieve machine multiple times to complete multiple frequency screening at one time.

The screens can be made up to 12 layers. And one screen mesh can be up to 6 composites, two screens can be up to 4 composites, three screens can be up to 4 composites, and four or five screens can be double composited, which makes the output larger, to achieve the effect of one compound screener is equivalent to multiple ordinary single-frequency screener.

| Layers | Model | Screening Area for Single Layer (m2) | Power (KW) | Frequency (r/min) | Dimension (mm) |

| 1~6 | AF-1025 | 2.5 | 3 | 180~330 | 3400*1700*2000 |

| AF-1030 | 3 | 3 | 3900*1700*(2000~3600) | ||

| AF-1036 | 3.6 | 3 | 4500*1700*(2000~3600) | ||

| AF-1230 | 3.6 | 4 | 3900*1900*(2000~3600) | ||

| AF-1236 | 4.3 | 4 | 4500*1900*(2000~3600) | ||

| AF-1530 | 4.5 | 5.5 | 3900*2200*(2000~3600) | ||

| AF-1536 | 5.4 | 5.5 | 4500*2200*(2000~3600) | ||

| AF-1830 | 5.4 | 7.5 | 3900*2500*(2000~3600) | ||

| AF-1836 | 6.48 | 7.5 | 4500*2500*(2000~3600) | ||

| AF-2030 | 6 | 7.5 | 3900*2700*(2000~3600) | ||

| AF-2036 | 7.2 | 7.5 | 4500*2700*(2000~3600) | ||

| AF-2040 | 8 | 7.5 | 5100*2700*(2000~3600) |

Note: The data above is for reference only. Our company reserves the right to modify.

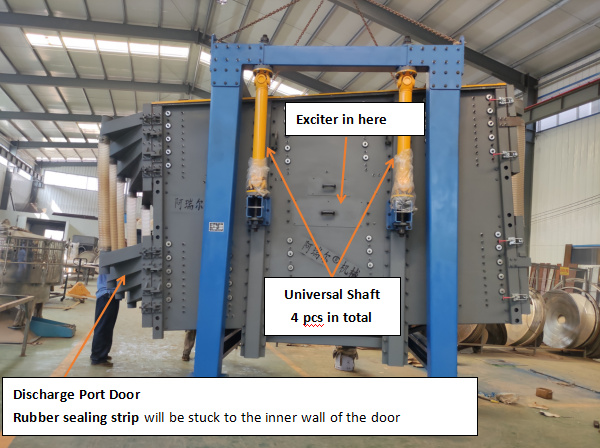

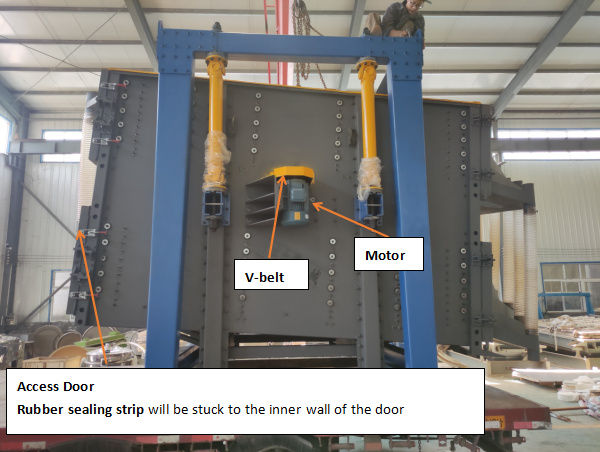

Details of Our Gyratory Sifter

Application

The high efficiency gyratory screener is a new type of high standard and large capacity screening equipment. It is widely used in chemical, metallurgical, abrasive, mining, quarrying, clay, glass, building materials, medicine, food processing, grain, plastics and other industries of fine classification, especially suitable for the most demanding screening requirements such as silica sand, frac sand, ceramic proppant, activated carbon, chemical fertilizer, limestone, petroleum coke, plastic granules, polyvinyl chloride powder, salt, sugar and so on.

Delivery Photos